By Anthony Gair;

(A) THE RECALCITRANT WORKER DEFENSE

(1) A BRIEF HISTORY

In order to understand the break from precedent by the Court of Appeals in 2004, it is useful to understand the history of the recalcitrant worker defense. For years the leading recalcitrant worker case was Smith v. Hooker Chemicals and Plastics Corp., 89 A.D.2d 361, 455 N.Y.S.2d 446 (4th dept. 1982); app. dismd. 58 N.Y.2d 824. The rule enunciated therein was that the “….the statutory protection (afforded by §240) does not extend to workers who have adequate and safe equipment available to them but refuse to use it.”

The facts in Smith are important in order to understand how the Court of Appeals in decisions between 2004 and 2009 expanded the reach of the recalcitrant worker defense by relying on cases such as Smith, while ignoring the facts upon which the holdings were based, thereby in effect failing to follow long established precedent.

For example, in Smith the plaintiff went up on a roof despite the fact that safety equipment had been removed and after a co-worker had refused to do so unless the safety equipment was put back in place.

The Court’s holding was thus based on the fact the plaintiff knowingly chose not to use safety devices which he knew had been in place and were readily available. His accident was also contemporaneous in time with his refusal to use the safety devices which his co-worker insisted be in place before the co-worker got on the roof.

The Court of Appeals followed the reasoning of Smith for years, as did numerous Appellate Division cases.

In Gordon v. Eastern Railway Supply, Inc., 82 N.Y.2d 555, 606 N.Y.S.2d 127 (1993) the plaintiff was standing on a ladder leaning against a railroad car while using a hand-held sandblaster to clean the exterior of the car. He was injured when he fell from the ladder. In rejecting the defendant’s claim that the plaintiff was a recalcitrant worker, the Court stated:

“Defendants’ claim here rests on their contention that plaintiff was repeatedly instructed to use a scaffold, not a ladder, when sandblasting railroad cars. We have held, however, that an instruction by an employer or owner to avoid using unsafe equipment or engaging in unsafe practices is not a ‘safety device’ in the sense that plaintiff’s failure to comply with the instruction is equivalent to refusing to use available, safe and appropriate equipment (Stolt v. General Foods Corp., supra; see also, Hagins v. State of New York, 81 NY2d 921, 922-923). Evidence of such instructions does not, by itself, create an issue of fact sufficient to support a recalcitrant worker defense.”

Continue reading →

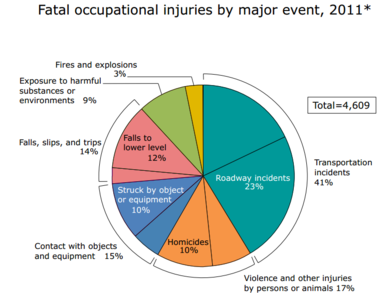

On April 10, at 11 a.m. EST, OSHA’s Director of Construction Jim Maddux, and NIOSH’s Director of Construction Safety and Health, Dr. Christine Branche, will co-moderate a webinar to discuss ways of stopping the leading killer of construction workers – falls from heights. To register for the free webinar and to learn more about efforts by OSHA, NIOSH, and CPWR to protect construction workers from fatal falls, visit the registration page.

On April 10, at 11 a.m. EST, OSHA’s Director of Construction Jim Maddux, and NIOSH’s Director of Construction Safety and Health, Dr. Christine Branche, will co-moderate a webinar to discuss ways of stopping the leading killer of construction workers – falls from heights. To register for the free webinar and to learn more about efforts by OSHA, NIOSH, and CPWR to protect construction workers from fatal falls, visit the registration page. New York Personal Injury Attorneys Blog

New York Personal Injury Attorneys Blog