Product Liability: New Safety Standard for Infant Bedside Sleepers will prevent Wrongful Death and Personal Injury

To prevent wrongful death and personal injury caused by defective or unsafe bedside sleepers a new federal mandatory standard to improve the safety of bedside sleepers was just approved by the Consumer Product Safety Commission (CPSC)

A bedside sleeper is a bassinet that is attached to an adult bed for parents to easily access their infant from their bed. It is intended for babies up to approximately 5 months.

Among the changes, the new standard includes modifications to the existing standard to address fabric-sided enclosed opening entrapment hazards. Between 2007 and 2009, the CPSC received 4 reports of infant wrongful deaths associated with fabric-sided openings on the products.

New York Personal Injury Attorneys Blog

New York Personal Injury Attorneys Blog

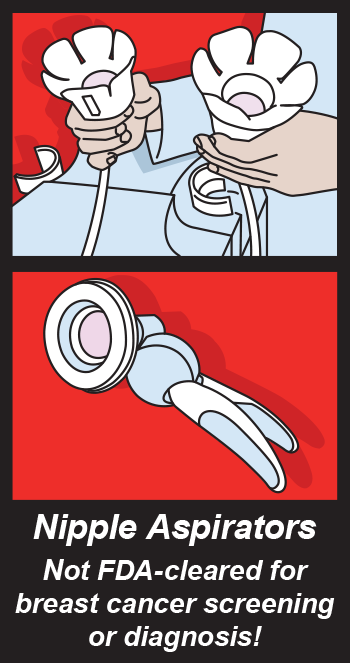

Some companies recently advertised the Nipple Aspirate Test as a method for breast cancer screening. The Nipple AspirateTest consists of using a breast pump to collect fluid from a woman’s nipple to screen for breast cancer. According the the

Some companies recently advertised the Nipple Aspirate Test as a method for breast cancer screening. The Nipple AspirateTest consists of using a breast pump to collect fluid from a woman’s nipple to screen for breast cancer. According the the  Toy testing, toy recalls, toy related injuries and toy shopping will be the subject of the first Google+ Hangout hosted by the CSPC. John Massale, A CSPC engineer, will describe the toy testing process and spokeswoman Nikki Fleming will there to answer all your questions.

Toy testing, toy recalls, toy related injuries and toy shopping will be the subject of the first Google+ Hangout hosted by the CSPC. John Massale, A CSPC engineer, will describe the toy testing process and spokeswoman Nikki Fleming will there to answer all your questions.

All GemStar Infusion Pumps that were either manufactured or had a pressure sensor replaced during servicing of the pump since January 1, 2009 are being subjected to a FDA Class I recall because of a potential pressure sensor calibration drift.

All GemStar Infusion Pumps that were either manufactured or had a pressure sensor replaced during servicing of the pump since January 1, 2009 are being subjected to a FDA Class I recall because of a potential pressure sensor calibration drift.