In Rodriguez v DRLD Dev., Corp., 2013 NY Slip Op 05548, The New York Appellate Division, First Department reversed the lower Court’s granting of summary judgment on her Labor Law § 240(1) claim holding that “it cannot be determined, on the extant record, whether plaintiff’s injuries were proximately caused by the lack of a safety device of the kind required by Labor Law § 240(1).” The plaintiff while working on a construction project tripped on a metal cable, dislodging a pile of sheetrock boards, which stood approximately eight feet high and were leaning against a wall, not in use. Plaintiff attempted to stop boards from falling with her hands and head, but she could not support their weight, and suffered injuries. This case illustrates the importance for a plaintiff to set forth the type of safety device that would have prevented the accident. Had this proof been offered the plaintiff would in all probability have won the motion since the Court stated as follows;

“The Supreme Court correctly held that section 240(1) applies to this case even though the sheetrock that fell upon plaintiff was located on the same first-floor level as plaintiff (see Wilinski v 334 E. 92nd Hous. Dev. Fund Corp., 18 NY3d 1 [2011]), and was not being hoisted or secured (see Fabrizi v 1095 Ave. of the Ams., L.L.C., 98 AD3d 864, 865-866 [1st Dept 2012]). We find no inconsistency between plaintiff’s deposition testimony and her averment that at the time the sheetrock fell on her, it was leaning against the wall and resting atop blocks of wood approximately two feet high, a sufficient height differential to implicate § 240(1)’s protections (see Lelek v Verizon N.Y., Inc., 54 AD3d 583, 584 [1st Dept 2008]).” Fortunately, for the plaintiff the 240(1) claim was not dismissed.

Compare this to Hugo v Sarantakos, 2013 NY Slip Op 05512, Appellate Division, Second Department in which The Court dismissed the plaintiff’s 240(1) claim. According to The Court “…the plaintiff, while standing on the second-highest rung of a 24-foot extension ladder, which he owned and brought to the work site, lost his balance and fell to the ground, allegedly sustaining serious injuries. Prior to the accident, the ladder did not move or slip, and it remained in an upright position after the plaintiff fell off of it.” In dismissing The New York Labor Law Section 240(1) claim the Court opined;

New York Personal Injury Attorneys Blog

New York Personal Injury Attorneys Blog

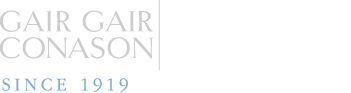

Safety Programs reduce construction accident injuries and significantly improve productivity and competitiveness according to the 2013 report

Safety Programs reduce construction accident injuries and significantly improve productivity and competitiveness according to the 2013 report

During Hurricane Sandy,

During Hurricane Sandy,  OSHA recently issued a

OSHA recently issued a